Ziehl-Abegg is one of the world’s leading companies in the production of industrial fans, motors, and control systems. In Vietnam, the company is committed to delivering the highest quality products that meet stringent international standards. To achieve this, Ziehl-Abegg Vietnam has invested in the LH108 Coordinate Measuring Machine (CMM) from Wenzel, equipped with the advanced PH10M Plus probe head, to ensure rigorous quality control throughout the manufacturing process.

|

|

| Figure 1: Some products of Ziehl-Abegg Vietnam company | |

The Importance of CMM in Manufacturing

A Coordinate Measuring Machine (CMM) is a crucial tool for inspecting and verifying the accuracy of mechanical parts. It measures geometric dimensions with high precision, detecting even the smallest deviations from the original design. In the manufacturing of industrial fans and motors, where every component directly impacts the performance and durability of the product, the use of a CMM is essential to ensuring quality.

Wenzel’s LH108 CMM with PH10M Plus Probe Head

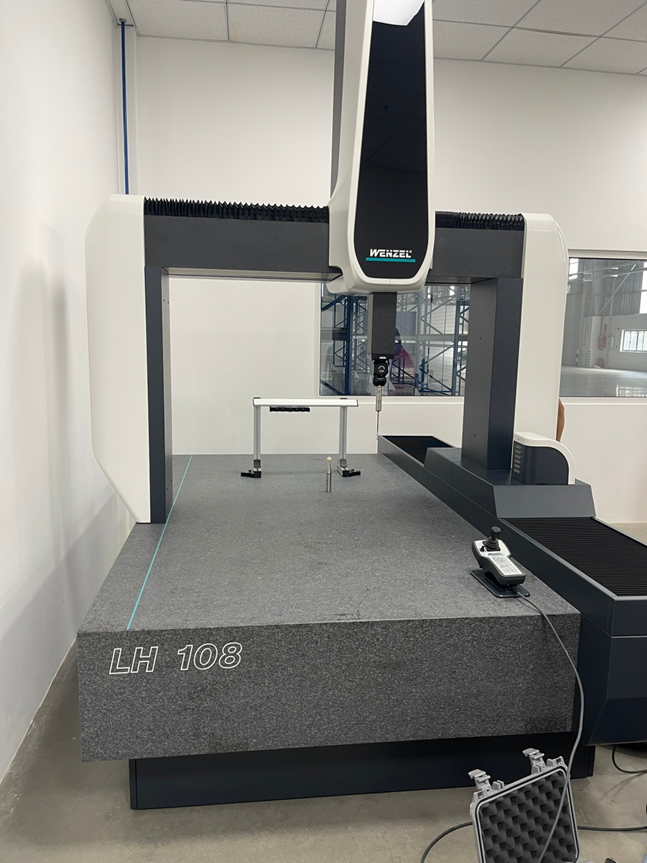

Ziehl-Abegg Vietnam has chosen the LH108 CMM from Wenzel, a renowned name in precision measurement technology. The LH108 model is known for its superior measurement capabilities and high reliability, making it ideal for inspecting complex parts in production.

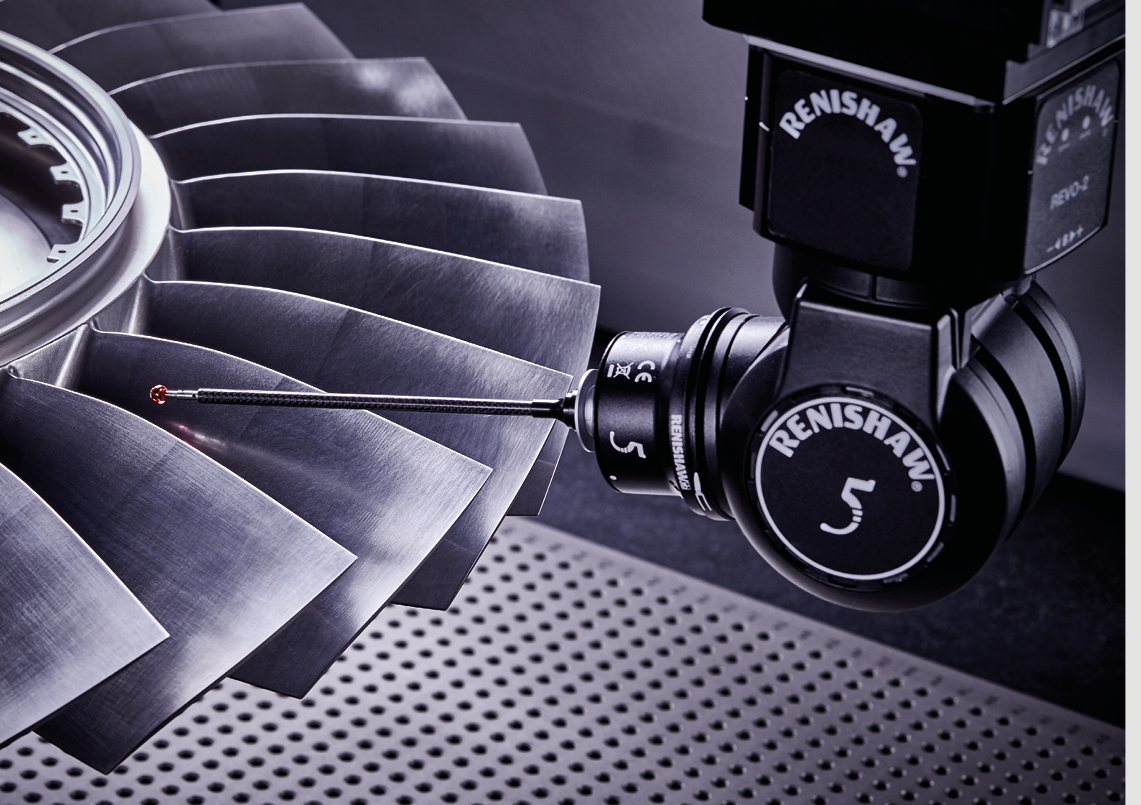

PH10M Plus Probe Head: The LH108 is equipped with the PH10M Plus probe head, one of the most versatile and advanced probe heads available today. This probe head can rotate 360 degrees, providing the ability to measure details from various angles, thus ensuring comprehensive quality control. Additionally, the PH10M Plus can accommodate various probe types, allowing the LH108 CMM to be flexible in inspecting Ziehl-Abegg’s diverse products, such as industrial fans, motors, and other components.

Figure 2: Wenzel – LH108 CMM with PH10M Plus measuring head

Application in Quality Control

The implementation of the LH108 CMM with the PH10M Plus probe head has brought significant benefits to Ziehl-Abegg Vietnam’s production process:

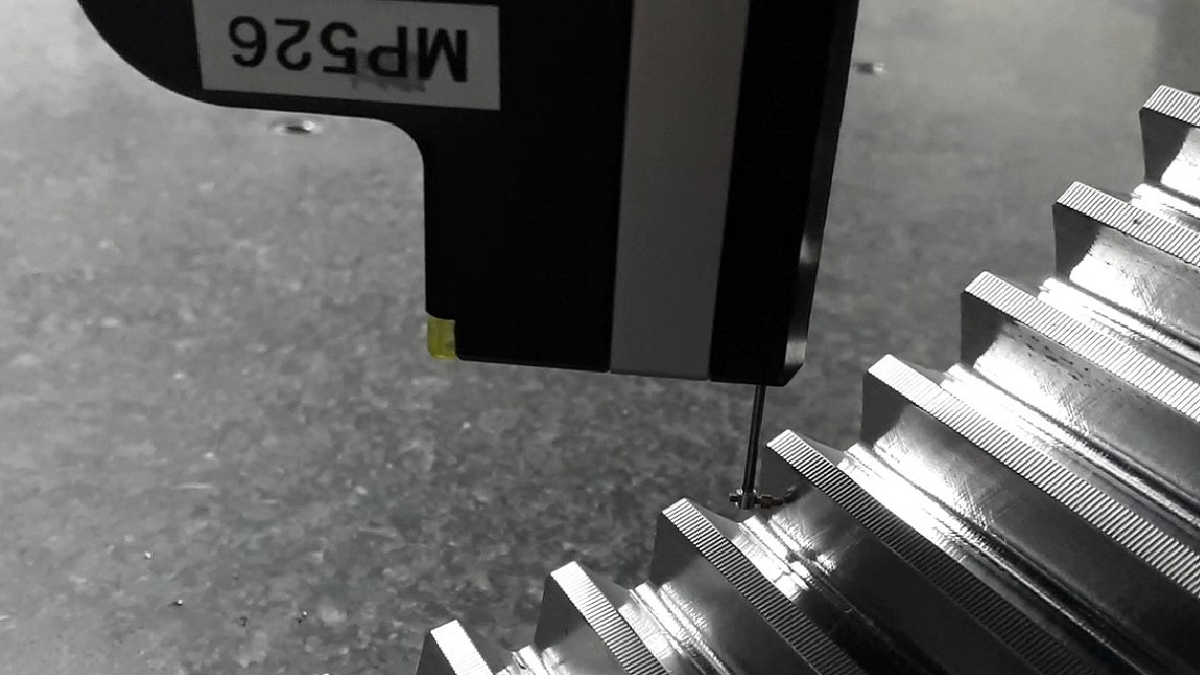

- Industrial Fan Quality Control: Ziehl-Abegg’s industrial fans require high precision in design and assembly. The LH108 CMM ensures that critical components such as fan blades, shafts, and housings meet strict technical specifications before assembly.

- Motor Quality Assurance: Motors are the core components of many Ziehl-Abegg products. With the precise and flexible measurement capabilities of the LH108 CMM and PH10M Plus probe head, the company can inspect motor components such as rotors, stators, and smaller parts to ensure they are free from any deviations, thereby enhancing motor reliability and performance.

- Production Efficiency Improvement: The use of the CMM allows Ziehl-Abegg to detect deviations early in the machining process, reducing waste and optimizing production efficiency. This not only saves costs but also ensures that product quality is

Benefits for Customers

By investing in advanced measurement technology like the Wenzel LH108 CMM, Ziehl-Abegg Vietnam not only improves product quality but also increases customer confidence. The company’s industrial fans and motors consistently meet or exceed international standards, offering optimal performance and long-lasting durability.

Figure 3: Engineer Wenzel and Engineer Ziehl – Abegg

Customers can be assured of the quality of Ziehl-Abegg’s products, thanks to the stringent quality control processes supported by cutting-edge technology. This helps the company maintain its leadership position in the market and expand its market share in Vietnam and the broader Asian region.

Conclusion

The use of Wenzel’s LH108 CMM with the PH10M Plus probe head is a significant step in Ziehl-Abegg Vietnam’s strategy to enhance product quality. Investing in this advanced measurement technology not only helps the company ensure product quality but also reinforces its commitment to customer satisfaction and the highest technical standards in the manufacturing industry.