Advantages of graphite electrodes in EDM applications.

1. The increasing complexity of mold geometries and the diversification of product applications lead to more and more precise sinker EDM machines. Graphite electrodes have the advantages of easy machining, high discharge machining removal speed, and small graphite loss, so some customer groups using igniters abandon copper electrodes and choose graphite electrodes. In addition, some special shape electrodes cannot be made of copper, but graphite is easy to mold and copper electrodes are heavy, not suitable for processing large electrodes, these factors have caused part of the customer base to rows with graphite electrodes.

2. Graphite electrodes are easier to machine and the processing speed is much faster than copper electrodes. For example, in the graphite milling process, the processing speed of graphite is 2 to 3 times faster than other metal processing and does not require additional manual processing, and the copper electrode requires grinding manpower. Similarly, if a high-speed graphite processing center is used to produce graphite electrodes, the speed will be faster and more efficient, but it will also not cause dust problems. In these processes, appropriate tool selection and graphite hardness can reduce tool wear and copper deterioration. If we compare the milling time of graphite electrodes and copper graphite electrodes, graphite is 67% faster than copper electrodes. In general, the machining process of graphite electrodes is 58% faster than that of copper electrodes. In this way, processing time is significantly reduced but also production costs are reduced.

3. The design of graphite electrode is different from the design of traditional copper electrode. Many mold factories often use copper electrodes of roughing and finishing with different reserves, and graphite electrodes are used with almost the same reserve. This reduces the number of CAD/CAM machine machining passes and for this reason alone is enough to improve the accuracy of the mold cavity to a large extent.

How to use the graphite material and other related factors to consider, of course the mold factory by converting the copper electrode of the graphite electrode. First of all, it needs to be clear. Nowadays, a part of the customer group using electric spark machines uses electric discharge machining with graphite electrodes, eliminating the mold cavity polishing process and chemical polishing can still achieve a perfect finish. desired surface finish. Without increasing the time and polishing process, the copper electrode cannot produce such a workpiece. In addition, graphite is divided into many different grades; In a specific application, use appropriate levels of spark and graphite discharge parameters to achieve the ideal processing effect, if the graphite electrode igniter uses operating personnel and electricity poles with the same parameters, the results will be disappointing. If the material of the electrode is strictly controlled, the graphite electrode can be arranged with no loss (less than 1%) in roughing, but the copper electrode must not be used.

Graphite has the following coppers that cannot be matched in terms of quality characteristics:

- Machining speed: high-speed milling and rough machining are 3 times faster than copper; The milling process speed is 5 times higher than the copper process.

- Good machinability can achieve complex geometric patterns.

- Light weight, less 1/4 copper density, electrode holder

- The number of individual electrodes can be reduced, as they can be packaged into an assembly of electrodes.

- Good thermal stability, no deformation and no burrs.

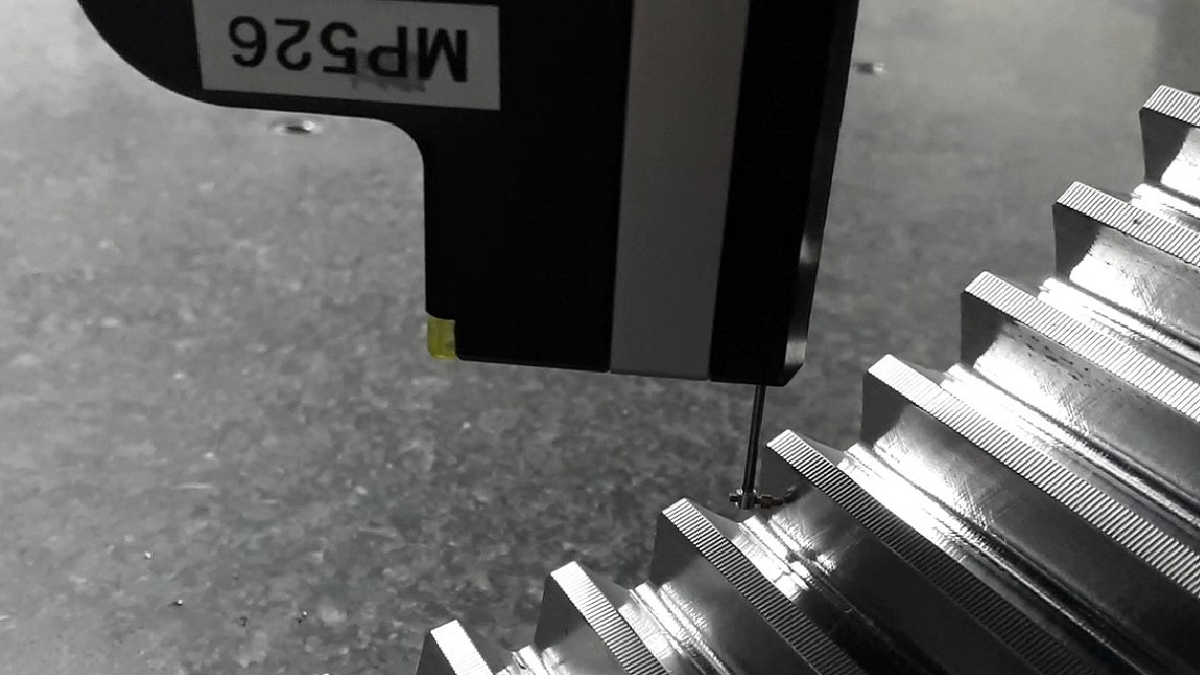

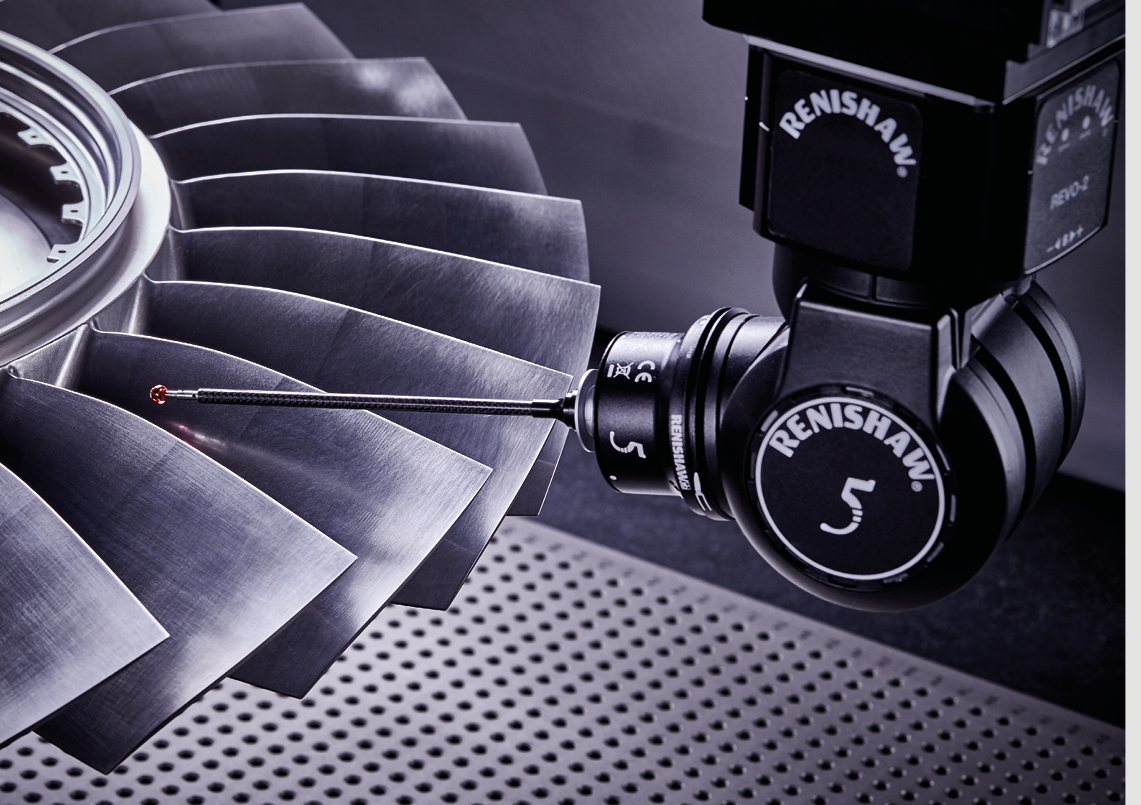

Below are some pictures of graphite electrodes as follows:

|

|

| EDM-AF5® | EDM-2® |

|

|

| EDM-4® | EDM-C3® |