MAINTENANCE AND REPAIR SERVICES, CALIBRATION, ADJUSTMENT OF 3D CMM MEASURING MACHINES

|

With a team of experienced and highly specialized genuine training technicians, Wenzel Vietnam is committed to providing the best quality maintenance and repair services, ensuring that customers’ 3D CMM measuring machines always operate effectively and efficiently. achieve accurate measurement results.

The most important thing for CMM measuring machines is reliability, so regular maintenance of CMM measuring machines is extremely important in production, to ensure smoothness in the factory. Here we provide maintenance and repair services of 3D CMM measuring machine. |

PERIODIC MAINTENANCE SERVICE WENZEL 3D CMM MEASURING MACHINE

CMM machine maintenance is necessary, because CMM is specialized equipment for reliable error testing often used in test units at manufacturing units or product quality control rooms.

When operating a 3D CMM meter, CMM maintenance is essential to optimize working efficiency, limit problems occurring when operating the machine and maintain the life of the equipment. If not maintained regularly and adequately, your CMM machine will be at high risk of damage, errors affecting production quality and additional overall operating costs

Wenzel Vietnam provides periodic maintenance packages to check and calibrate 3D CMM measuring machines. With modern equipment and standardized processes, customers can have the clearest report on the status of their CMM machines in use.

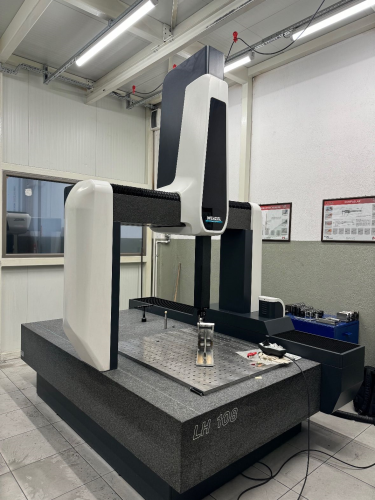

WENZEL LH 108 3D CMM measuring machine

REPAIR SERVICE AND SUPPLY OF SPARE PARTS WENZEL 3D CMM MEASURING MACHINE

Evaluated by a genuine expert, your CMM machine will be cared for for life

– Temperature balance error: Check and recalibrate the temperature balance on the 3D CMM measuring machine to ensure stability and accuracy in different operating environments.

– Measurement accuracy errors: Identify and fix measurement accuracy errors by recalibrating the measuring head, coordinate system and other machine components to ensure accurate and consistent measurement results.

– Control system and software errors: technician team will check, update and repair the control system and software on the 3D CMM measuring machine to ensure smooth and accurate operation. At the same time, resolve errors related to software performance, compatibility and features.

– Mechanical and structural system errors: Evaluate and repair mechanical and structural system errors such as sensors, moving shafts and other parts to ensure stable and accurate operation of the meter .

Guaranteed to provide genuine replacement parts and equipment with long-term warranty.

CALIBRATION AND CORRECTION SERVICE WENZEL 3D CMM MEASURING MACHINE

Calibration is necessary to be performed regularly every year to ensure reliability and control product quality in the most optimal way.

Calibration: After the calibration results are obtained, the engineers proceed to compensate for errors with software in small error fields. However, in cases with large errors, it is necessary to check and re-adjust the hardware.

Note: the above steps are all performed by the company’s experts, who have been trained and worked for many years at Wenzel Vietnam.