In today’s high-tech industries such as semiconductor and electronics manufacturing, pharmaceuticals, and biotechnology, the demand for clean environments and precise quality control is stricter than ever. Investing in a particle counter is no longer optional — it’s an essential requirement to ensure product integrity and compliance with international standards.

1. Particle Counters – The “Gatekeepers” of Cleanroom Quality

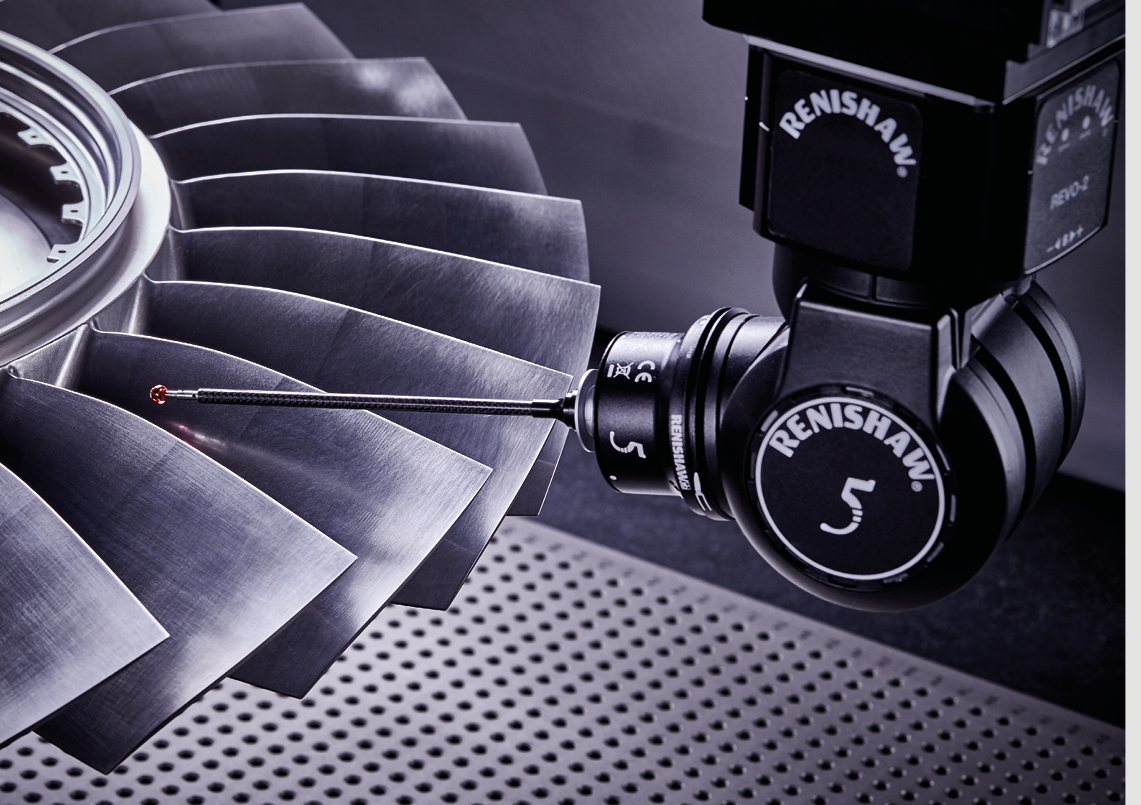

Particle counters detect and quantify microscopic particles in air or liquid to evaluate the cleanliness of a controlled environment.

With the ability to measure particles as small as 0.1 microns, they act as the “gatekeepers” that ensure every product is manufactured in the cleanest possible conditions.

Even the smallest deviation in particle control can lead to:

-

Reduced product quality

-

Process failures in high-precision manufacturing (e.g., microchips, injectable drugs)

-

Compliance risks with GMP, ISO Class, or FDA standards

2. The True Cost of Investment – Beyond the Price Tag

Many businesses hesitate at the upfront cost of a particle counter. However, the real value lies not in the purchase price, but in the long-term return on investment it delivers:

-

Early detection of contamination issues to minimize product loss

-

Stable cleanroom performance and reduced downtime

-

Optimized inspection and calibration costs — especially when combined with professional maintenance services from GERA Hi-Tech Vietnam

-

Strengthened customer trust through transparent, verifiable quality data

3. Profit Through Proactive Quality Control

Investing in a particle counter means investing in efficiency, reputation, and sustainable growth.

A modern particle monitoring system empowers manufacturers to:

-

Make data-driven decisions based on real-time insights

-

Improve traceability and regulatory compliance

-

Minimize production risks and increase profit margins

At the strategic level, this investment is not an expense — it’s a profit generator that enhances operational performance and long-term competitiveness.

4. GERA Hi-Tech – Your Trusted Partner in Calibration, Maintenance, and Cleanroom Quality Management

GERA Hi-Tech Vietnam is an ISO/IEC 17025:2017 accredited service provider specializing in calibration, maintenance, and cleanroom quality assurance.

As the trusted partner of leading technology, manufacturing, and pharmaceutical companies in Vietnam, we are committed to delivering:

-

High-quality particle counters from Lighthouse Worldwide Solutions

-

End-to-end solutions including APC, LPC, and ActiveCount systems

-

Fast, precise, and professional technical services

-

Training and technical support to help plant engineers operate with confidence

Conclusion

Investing in a particle counter is more than a cost — it’s a strategic move to enhance competitiveness, reduce risk, and optimize profitability.

With GERA Hi-Tech Vietnam as your partner, every investment becomes a sustainable, value-driven solution that delivers real operational impact.

👉 Contact GERA Hi-Tech today to receive expert consultation on particle monitoring and calibration solutionstailored to your cleanroom system.