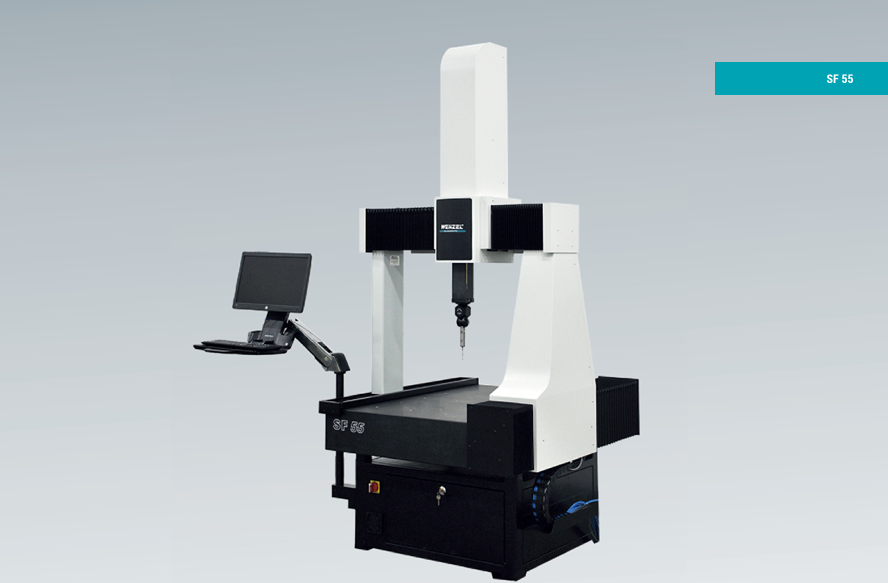

WENZEL SF 55 – Measure in the production environment

CMM SF 55 WENZEL

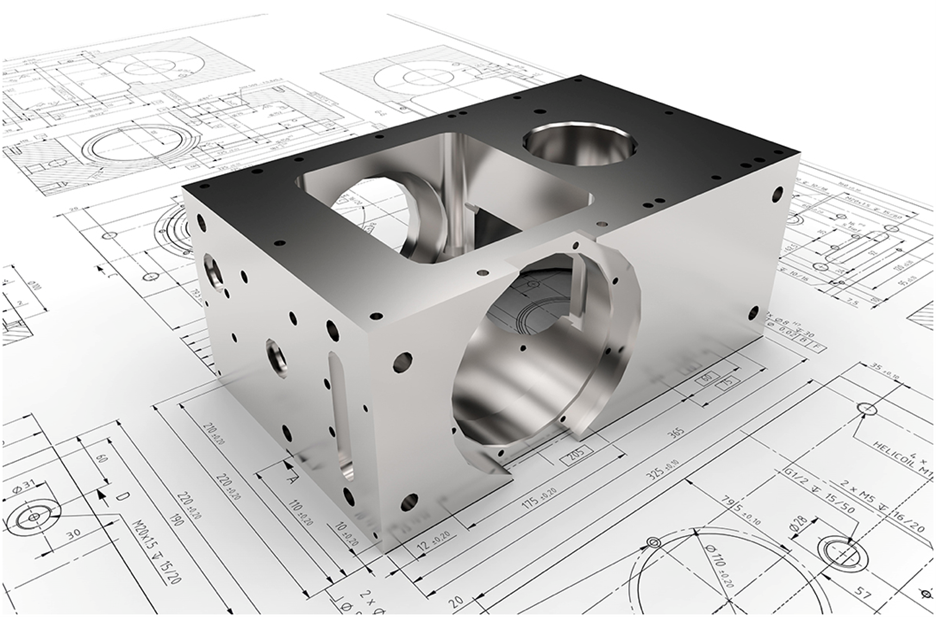

The SF 55 is a CNC bridge measuring device for use in a production environment and can be equipped with both tactile and optical sensors. The corrosion-free guides of the machine are made of granite and hand lapped with high precision. The guide ways are completely covered and protected against contamination.

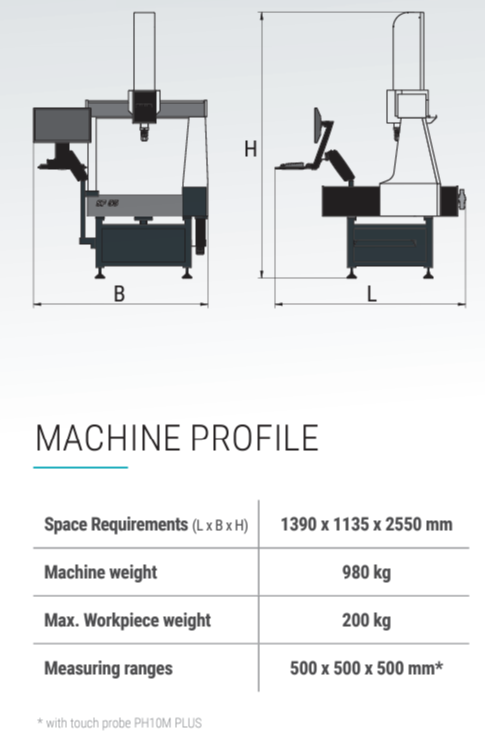

The controller and PC are integrated into the machine for a minimum footprint. The space requirement is low, as is the price-performance ratio. The SF 55 has passive vibration damping and can optionally be equipped with active vibration isolation.

FEATURES

- Cost-effective entry into coordinate measuring technology due to excellent price-performance ratio

- Flexible and universally applicable in the workshop and in production

- High measuring throughput with scanning measuring heads

- High accuracy over a wide temperature range due to the use of granite in all axes

- Compact design with small footprint

FIELDS OF APPLICATION

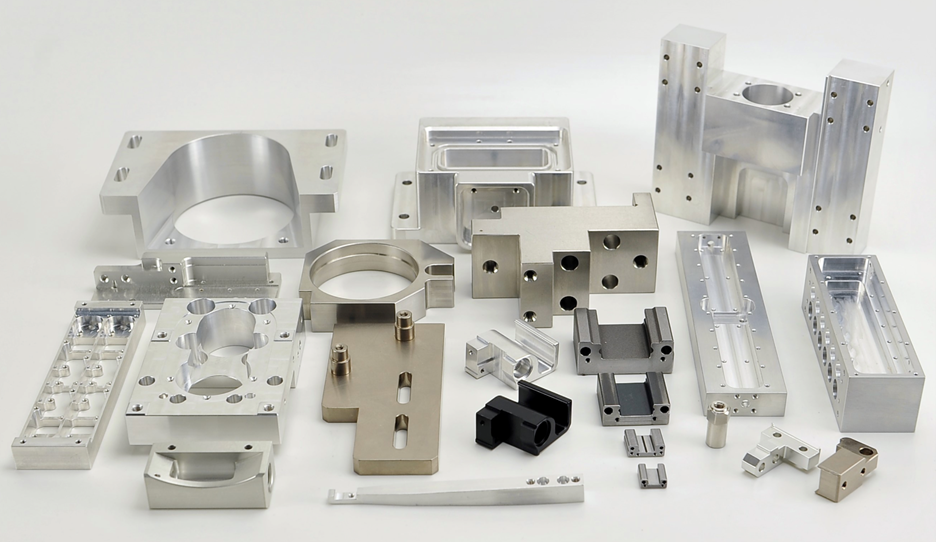

The SF 55 can be used universally. Prismatic and free-form workpieces can be measured with the coordinate measu- ring machine in a production environment, for incoming goods and for classic quality assurance, both for series of and individual parts.

| Advanced processing | Gearboxes | Machine components |

|

|

|

|

|

STRENGTH

High flexibility

Height-adjustable operating arm

Low operating costs

Versatile sensor options

Suitable for automation and integration into the line

|